Sinorock Overview

Self Drilling Anchor System

Structure

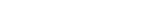

Self drilling anchor system is composed by hollow anchor bar, coupler, nut, drill bit, plate, and centralizer, It can combine drilling, grouting and anchoring in one process. Self drilling anchor system is safe, efficient and convenient. It is suitable for broken rock, loose soil and geological conditions where are difficult to drillholes. It helps to ensure anchoring effect in complex ground conditions and achieving best construction result.

Sinorock® divides our self drilling anchor system into R thread self drilling anchor bolt and T thread self drilling anchor bolt. The sizes of our self drilling anchor bolt include R25, R32, R38, R51, T30, T40, T52, T73, T76, T103, T111, T127, T130, T150 and T200. We can choose different product size and type of self drilling anchor system according to different engineering requirements.

Features And Advantages

Self drilling anchor bolt, which combines drilling, grouting and anchoring together, is suitable for broken rock and conditions which are difficult to drill holes. Casing pipe wall protection is omitted in construction, which greatly improves the construction efficiency.

Self drilling anchor bolt has a rich variety of drill bits, and drill bit can be selected according to the properties of rock and soil, which can improve the drilling efficiency.

Self drilling anchor bolt can fill cracks, consolidate rock mass and soil layer through pressure grouting, and has good grouting spreading radius and reliable anchoring quality.

The hollow anchor bar can be cut arbitrarily and lengthened by the coupler. Therefore, self drilling anchor bolt is suitable for the construction in the narrow space which the large equipment can not enter.

Corrosion Resistance Technology

During application, the biggest influence on the service life of anchor bolt is the corrosion of surrounding environment, so it is especially important to have anti-corrosion anchor bolt. To meet customer's demand, SINOROCK specializes in providing a variety of anti-corrosion anchor bolt system, such as hot dip galvanizing anchor bolt , epoxy coating anchor bolt and the duplex(multiple) coating anchor bolt.

Epoxy coating anchor bolt is mainly used in industrial and civil construction, general structures and roads, bridges, ports and docks in humid or corrosive media.

Hot dip galvanizing anchor bolts are suitable for geotechnical engineering applications where longer service life is needed and the surrounding environment is complex, such as roads, railways, hydro-projects and other buildings that may be affected by seawater.

The duplex coating anchor bolt is a combination of hot-dip galvanizing and epoxy coating. It is commonly used in the permanent support of hydro-projects, underwater tunnels, subway tunnels and some important buildings affected by groundwater for a long time. And it is also widely used in harbors, wharfs, offshore buildings that are corroded by seawater.

Larger Diameter Self Drilling Anchor System

Larger diameter self drilling anchor bolt system we refer to which the outer diameter of hollow bar is not smaller than 103mm. Now the biggest we can provide is 200mm. Customized products are also available based on your specific requirements. The whole system includes hollow anchor bar, coupler, nut, drill bit, plate and centralizer. Large diameter self drilling anchor bolt system has high tensile and compressive load and good shearing resistance. It is widely used in foundation piling.

Product Application

Foundation stabilization

Abutment reinforcement

Wind power tower pile foundation

Transmission tower pile foundation

Stainless Steel Self Drilling Anchor Bolt System

Stainless steel self drilling anchor bolt system is one of our self drilling anchor bolt systems. The product has a better anti-corrosion performance, and it can resist the corrosion of air and chemical medium. It's not easy to rust and is good in appearance. It mainly includes stainless steel anchor bar, stainless steel coupler, stainless steel nut, stainless steel plate and other stainless steel accessories.

It has all advantages of self drilling anchor bolt system

It has good corrosion resistance and oxidation resistance, and is suitable for coastal and other corrosive environments.

Stainless steel system has better longevity, and can replace other anti-corrosion bolts such as hot-dip galvanizing.

Compared with common carbon or alloy steel anchor bar, stainless steel has excellent weldability.

High strength and wear resistance.

Product Application

Corrosive projects such as ocean and lake.

Building foundation stabilization under heavy corrosive environment

Repair of existing building with permanent support requirements

Anti-floating pile under periodic variation of groundwater

Corrosive Soil and rock reinforcement projects with aggressive geological conditions

Transmission tower base with high corrosion resistance requirement

Let's Make Something Great Together. Get in Touch With Us and Send Some Basic Info For a Quick Quote.

Request A QuoteApplication

Self-drilling hollow anchoring system is mainly used for tunnel and underground engineering, slope engineering, ground and foundation engineering, etc. It can be used for pre-construction support and can effectively enhance the stability of soil and rock mass.

Tunnel and Underground Project

Tunnel and Underground Project

It is mainly used for initial support of tunneling. High pressure grouting is achieved through the hollow bar to strengthen the soil or rock mass to ensure the surface stability. According to the types of support in the tunnel, it can be divided into fore piling, radial support, tunnel-face support, locking the foot support and reinforcement of the tunnel portal.

Slope Stabilization Project

Slope Stabilization Project

It is mainly used for slope project with poor geological environment. Slope stabilization is ensured by the entire anchoring system itself subjected to tensile and shear forces. It can be used as soil nail support, slope protection barrier, falling rock protection, retaining wall, embankment stability, roadbed reinforcement and other different application scenarios.

Ground and Foundation Project

Ground and Foundation Project

It is mainly used for micro pile. Pressure, tension or periodic loads can be transferred to the surrounding soil, transferring structural loads to the underlying foundation structure and limiting the deformation of the building. It can be used as new building pile foundation, existing building structure repair, tower foundation, bridge reinforcement, soundproof wall foundation, protective screen pile foundation, anti-floating pile foundation, retaining beam anchoring and other different structural scenes.

Why Choose Us

Our Company

Our Company

Sinorock is an experienced manufacturing and trading company specialized in the research & development production and sales of self drilling anchor bolt and other anchoring products.

Sinorock adopts the advanced production equipment and stringent quality control procedures, to ensure that we can provide customers low-cost, and high quality construction materials, so that the equipment used in the construction is safe and efficient. Meanwhile, we devote ourselves to provide clients with a one-stop solution for geotechnical anchoring.

Our Factory

Our Factory

Sinorock owns a variety of testing equipment such as tension tester, spectrograph, material analyzer and so on. All products will be inspected comprehensively. We have hundreds of professional processing equipment.

Accessories processing adopts CNC equipment and appropriative production machine.Thanks to the circulating and filtering systems Sinorock can achieve zero release. The special processing and combination technology also improve the utilization rate of the material.

A Perfect Quality Control Process

Sinorock quality control process mainly include incoming inspection, process quality control and outgoing inspection.17 inspection procedures, together with 5 trials, are required in the whole inspection process, which makes at least 60 record forms; Each program, will be executed strictly according to our standing operating procedure.

Incoming Inspection

Sinorock appoints inspector and purchaser to follow up the whole course of raw material production and test the finishedproducts of every batch.

Process Quality Control

Sinorock implement "three inspection system", which are self-checking, mutual inspection and specialized inspection

Outgoing Inspection

All products have their valid identities to ensure product traceability.

Certification

Comprehensive Service System

Set up the concept of after-sales service, unify after-sales service standards, dedicate to customized service concept, fully ensure customer service satisfaction, from three aspects of pre-sales, sales, after-sales, all-round launch customer service work combined with customer region and grade multi-dimension, and ultimately create the Sinorock brand of featured after-sales service.

![]()

Pre-Sales Service

- 1Counselling Service

- 2Quotation

- 3Follow up the Customer

- 4Customer Reception

![]()

Sale In Service

- 1Quick Order Arrangement

- 2Timely and Effective Follow-up as well as Feedback

- 3One-to-one Professional Services

- 4Trade Logistics Integration

- 5Customized Service

![]()

After-sales Service

- 1Customer Complaint Treatment

- 2After-sales Investigation

- 3Customer Service

- 4Holiday Greetings

Contact Us

Contact us now if you have any questions about our company and products.We will retain your information completely private.

Phone

+86-379-60105687Fax

+86-379-64386676E-mail

sinorock@sinorockco.comAddress

No.1703, Building 3, No. 1 Fenghua Road,High-tech,District , Luoyang , China (Henan)Pilot Free Trade Zone, Henan Province, P.R. China.